Our Company Statement on Diversity, Equity, and Inclusion

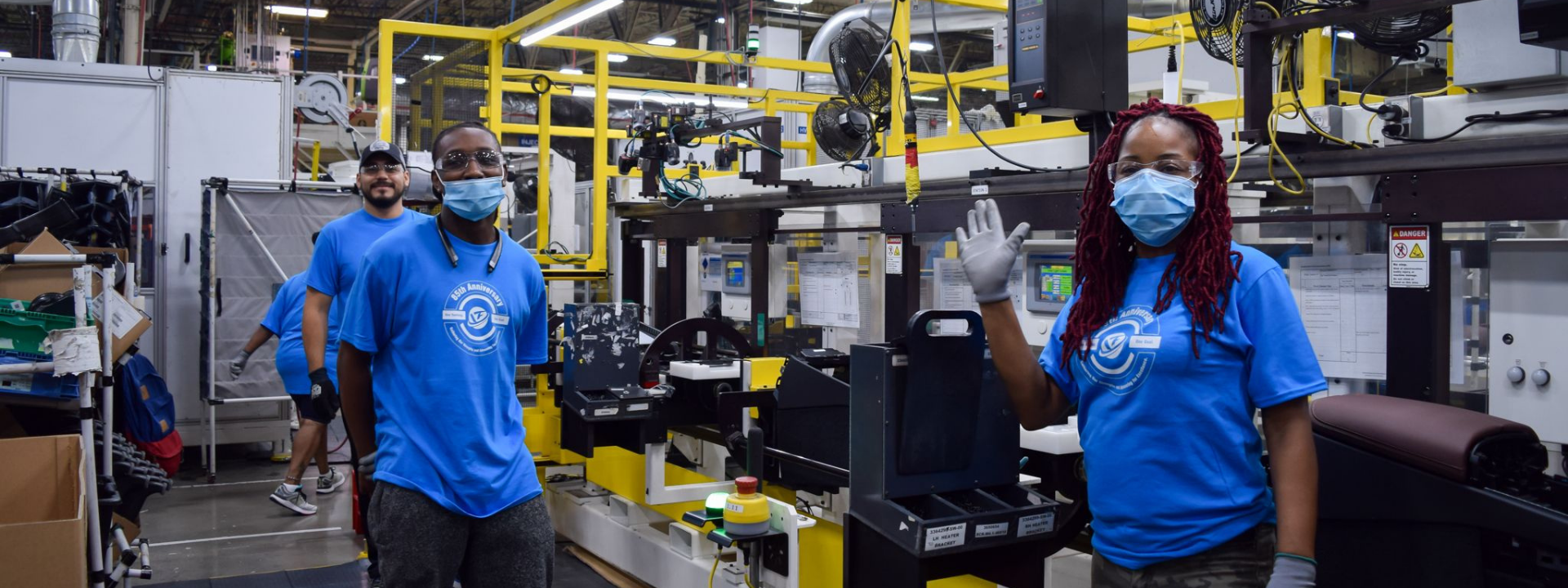

We use the phrase One Yanfeng to describe our globalization; bringing together our competencies, business units, and our people. One Yanfeng is also how we communicate our commitment to diversity, equity, inclusion, and belonging. As an organization, as a global community, we will work together, as one, to provide an inclusive culture and equitable talent journey; one that values employees for who they are and is rooted in trust and respect.

Explore your career opportunities

Find a role that will give you a real sense of purpose, challenge you with global projects and provide an opportunity to drive progress.

Grow professionally and develop new skills within a rich, dynamic workplace culture. Get in the driver’s seat to career success with us.

Get the professional experience while studying and set your career in motion. Check out our event calendar to meet us.

Become a part of a growing team that's committed to quality, innovation, and collaboration.

LinkedIn

LinkedIn

Facebook

Facebook

Instagram

Instagram

YouTube

YouTube